Indian automotive landscape

The Indian automotive industry imported around $17.5 bn worth of components in 2019. The supplier base is not too diversified for majority of the components. This was to drive volume-based price efficiencies; however, this strategy is highly exposed to risks emerging from disruptions in the markets supplying key auto components.

The impact of this pandemic is deep rooted. Indian automotive supply chain and manufacturing professionals have been evaluating the mid and long-term impacts of COVID-19 on procurement planning and supplier management, integrated sales and operations planning, manufacturing, logistics and distribution.

COVID-19 disruption: Impact on automotive supply chain

Disruption from COVID-19 can be observed both in supply and demand side characteristics Demand volatility due to evolving consumer sentiments, rapidly chaining supply constraints and manufacturing volatility steaming from forced plant shutdowns.

With major import nations under lockdown and long periods expected in the recovery process, Indian Automotive supply chain has come under intense stress. The after-effects of these disruptions led to

- Liquidity crunch and bankruptcy of a section of small and medium enterprises due to low capacity utilization and higher fixed costs

- Migration of out-contract laborers of the manufacturing sector leading to delays in delays in restart and under-utilization of the installed capacitates

- Stringent lending norms by banks and NBFCs leading to depressed sales in Tier 3 and rural micro markets

Traditionally, logistics cost in India has been comparatively higher than other neighboring nations. The key challenge for the Indian Automotive supply chain would now be to manage the cost escalation year on year in the long term.

Criss management- adapt and overcome

The auto industry needs to deploy crisis management, governance and supply chain intelligence. A critical first step would be to identify the company’s key direct suppliers and their dependencies — both in the supply side and in the demand side. Mapping of their ability to meet supply requirements and respond during potential risk scenario needs to be carried out in depth.

This will enable a flexible ecosystem of suppliers and distribution partners. Increased and real time visibility of their network will result in better preparedness in case of disruptions in specific nodes or routes. Organizations need to consider start-stop operation scenarios and its consequences on production planning, buffer inventory, forecasting to suppliers and an agile chain with optimized cost.

An agile supply chain strategy

A rapid assessment to gauge the impact of the disruption and the impact on suppliers and customers would be a critical step to determine the list of actions re-quired to enable an agile supply chain in the interim, for restarting operations also for scaling up as normalcy returns

Conduct an end-to-end risk assessment of supply chain covering demand and supply risks, operational performance, global trade implications, customer impact and people aspects

Identify crisis scenarios designed to stress test an operation’s ability to manage disruption and identify the gaps within the current supply chain model and quantify the impact

Build intervention business case to implement validated crisis response triggers including requirements, solutions and value proposition

Exploring agile and flexible supply and distribution network can drastically reduce the risk associated with unpredictability of demand. Being highly dependent on lowest cost supplier and minimal inventory might significantly impact the supply chain, as business environment deals with the dynamic demand characteristics of the market.

Critical success factors would be real-time visibility to critical data, enabling early warning signals and proactive management actions, i.e., control tower framework. Enterprises need to drive mindset change in supply chain planning to prioritize risk mitigation and business continuity over cost optimization, enabled through scenario based integrated planning.

OEMs also need to have visibility of Tier 2 suppliers to the extent that it affects the order fulfilment constraints for key Tier 1 suppliers in various demand scenarios. The coverage should help OEMs assess requirement of alternative second tier supply routes to prevent any disruptions in desired production output even when the supply side scenarios change due to unseen external circumstances.

Embracing digitization

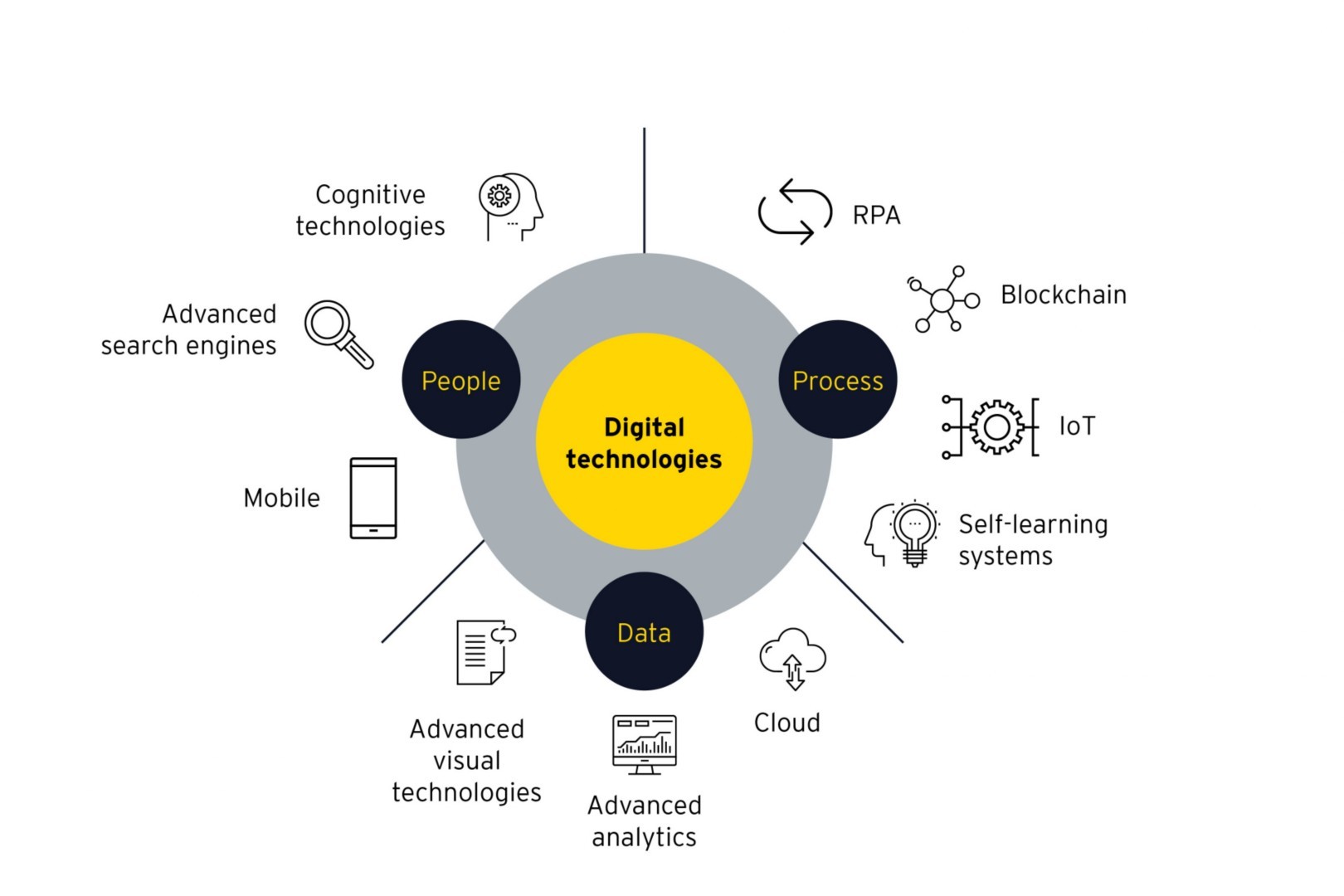

Digitization of the supply chain will provide the necessary edge to organizations to address the changing needs of the customers. Digital interventions across people, business process and data governance will underpin supply chain transformation.