Bigger benefits can be achieved if we use these technologies for simplifying and de-stressing life at the shop floor. It is therefore imperative to integrate operator experience with the best automation and digital solutions.

Digital manufacturing survey results

The findings of the report highlight the level of adoption of digital manufacturing and India’s preparedness level, the key driving factors, expectations on the benefits and existing challenges that manufacturers face in India.

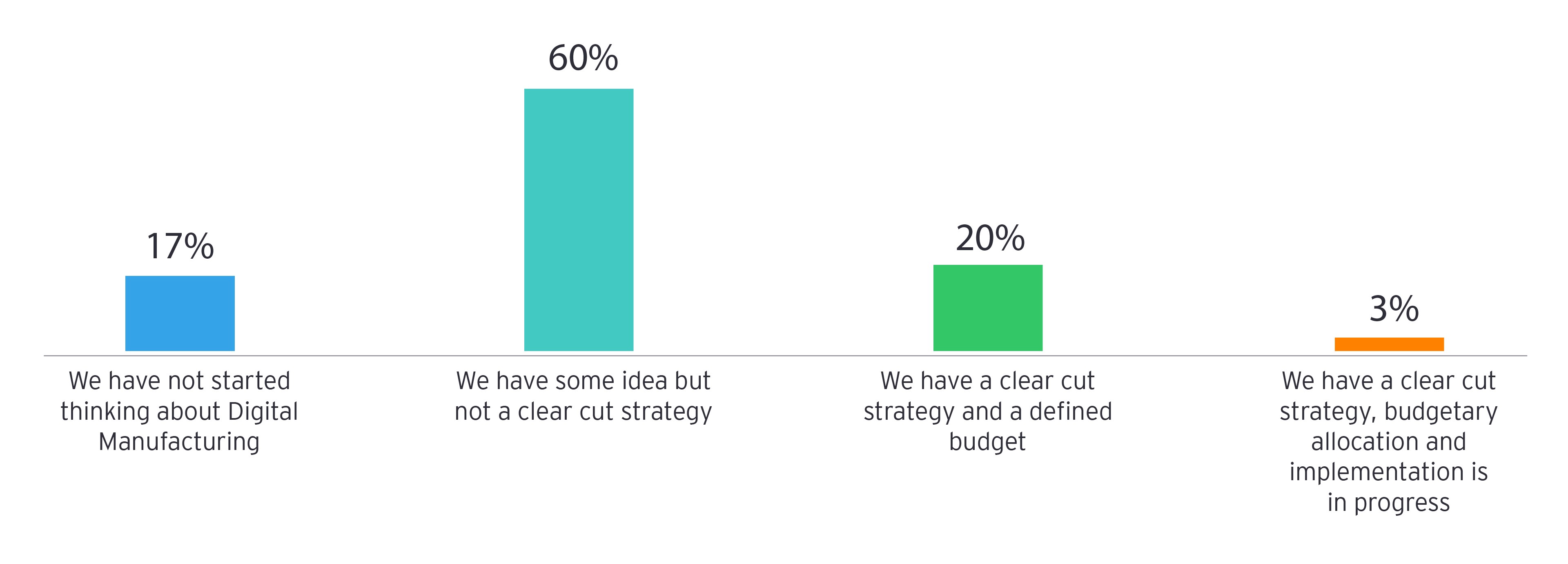

Does your company have a digital manufacturing strategy?

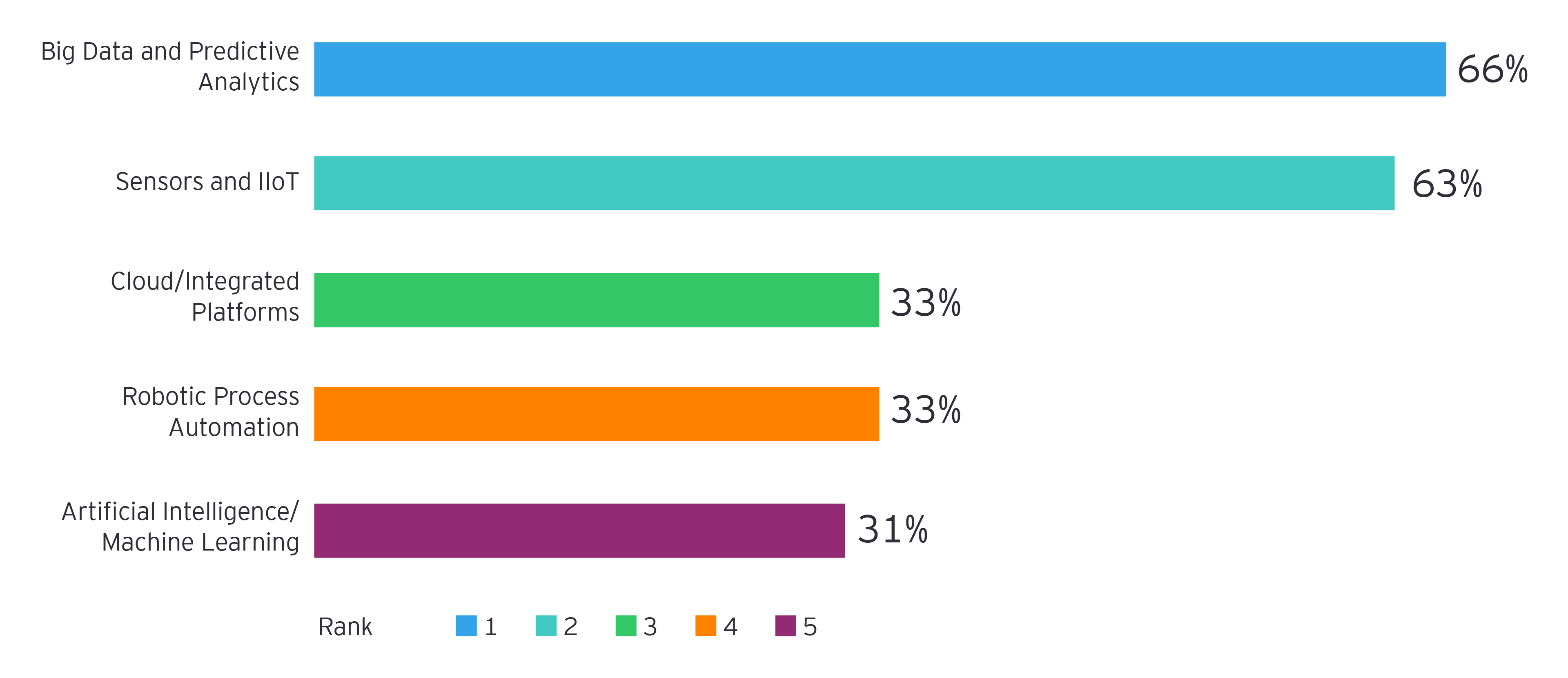

In what technologies would you like to invest in the next one or two years (based on the ranking, with rank 1 being the most important) to transform your current manufacturing process?

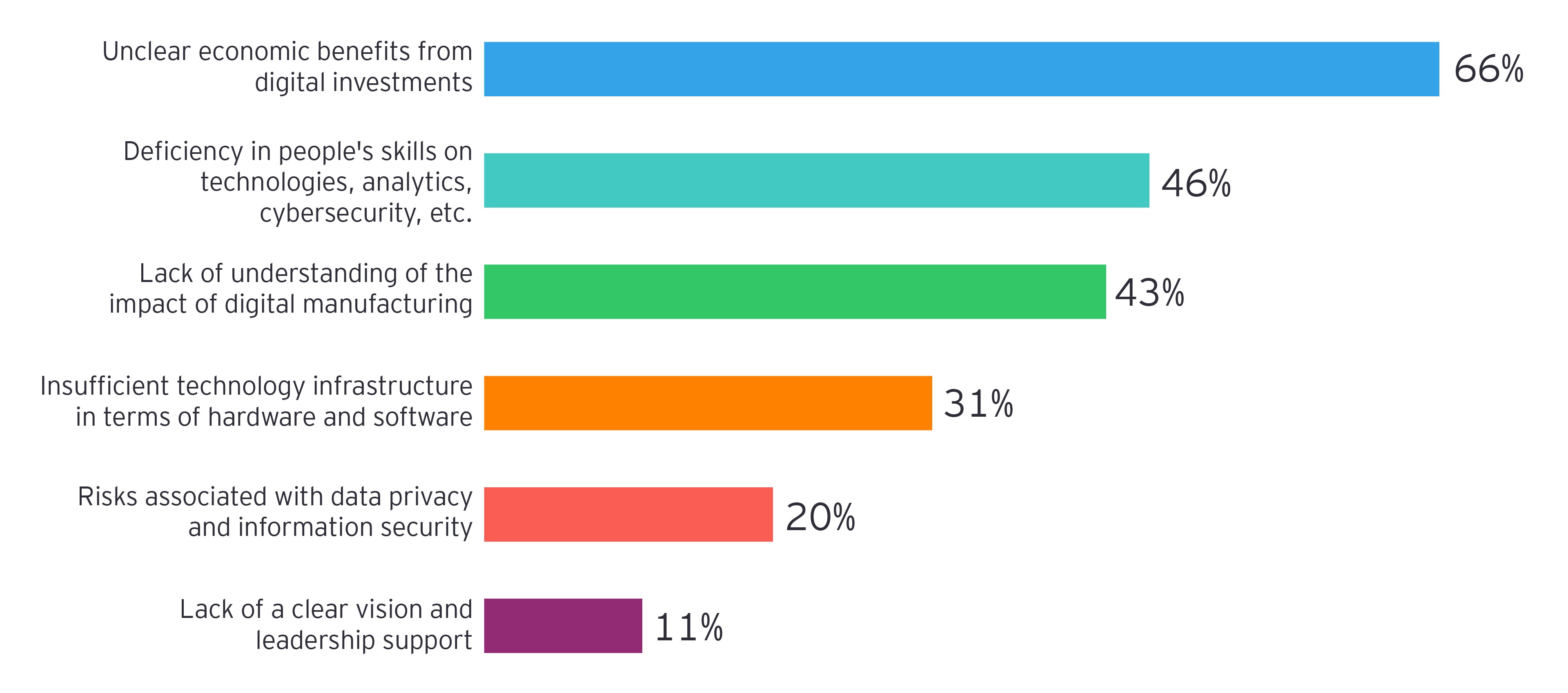

Identify the key challenges and risks associated in adopting digital manufacturing.

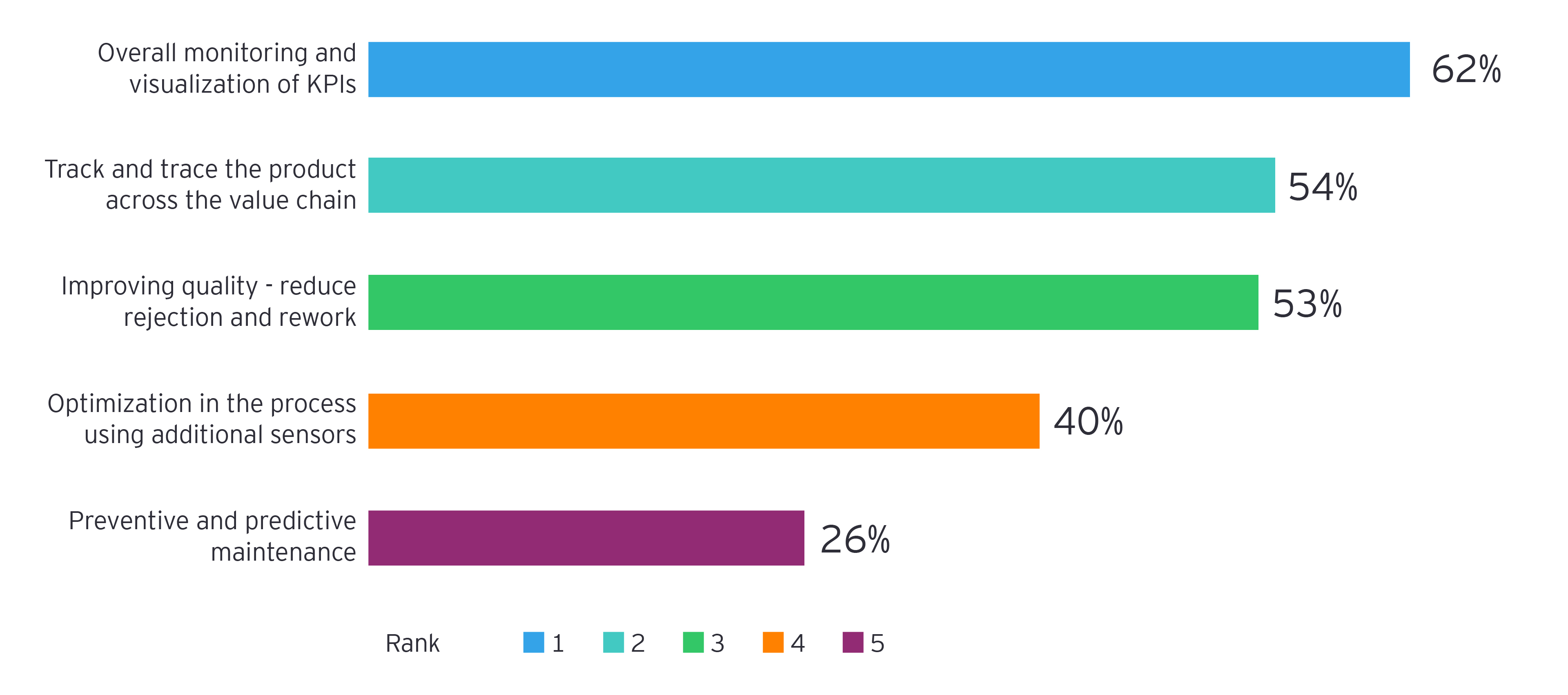

What areas do you think would your company benefit the most while adopting Digital Manufacturing (based on the ranking*)?

Leveraging Industry 4.0 technologies

The study provides an insightful reflection of the awareness, readiness and status of implementation of digital manufacturing in India. It is apparent that manufacturing leaders have started exploring the adoption of digital manufacturing in their organizations. Some of them even have a strategy and a budget ready for digital manufacturing initiatives. However, lack of clarity on the economic benefits of the investments required to integrate hardware, software and technology infrastructure with digital systems and decision intelligence capabilities is acting as a roadblock for these organizations to move towards the adoption of digital manufacturing. Industry leaders are employing emerging technologies to improve the monitoring of process performance through measurement and visualization of KPIs, performance tracking, throughput enhancement and quality improvement. However, there seems to be a wait and watch approach and a majority of leaders are waiting to confirm the success/failures of the existing PoCs before getting convinced about the adoption of emerging technologies such as AI, 3D printing, Machine Vision, and Augmented Reality at scale.

We believe that in an evolving world of well-connected consumers, systems and processes with tremendous ease in accessing information, manufacturing organizations are expected to be proactive, agile, flexible and adaptive. In order to meet these expectations, companies can leverage Industry 4.0 technologies to enable them to:

- Have real-time, on-demand information and visibility across the production chain

- Apply advanced analytics capabilities to refine process and production techniques

- Facilitate end-to-end integration with suppliers, channels, business partners and customers

- Gain agility in manufacturing processes like implementing new products, cutting down cycle and waiting times, changeovers, and feedback loops

- Reduce wastages (rejects, reworks, idle time, excess inventories) and be cost efficient

Digitizing the value chain is one of the top priorities of the operations-strategy agenda in manufacturing companies. Progressive organizations are moving from piloting of point solutions to delivering sustainable impact.

The time to act is now and as a first leg of the journey, it is important for companies to identify and onboard the right talent and collaborate with the right partners who could provide them with a platform, hardware, sensors, and an application. The need of the hour is to quickly formulate their digital manufacturing strategy that takes cognizance of specific needs and utilize data as the central asset. While having the right strategy is only a beginning, a clear roadmap defining the functions and combination of technologies would help companies to move forward.

Summary

Concepts such as Industry 4.0 and Smart Factory, which interconnect the shop-floor ecosystem through emerging technologies are now a reality. Digitization continues to transform manufacturing processes around the world leveraging technologies such as Industrial Internet of Things (IIoT), artificial intelligence, advanced robotics, etc. However, the adoption of digital technologies in India is still in its infancy. Going by the success stories though, it is perhaps essential for manufacturing organizations in India to first understand and then embark on this digital transformational journey to remain competitive and attain world-class status.