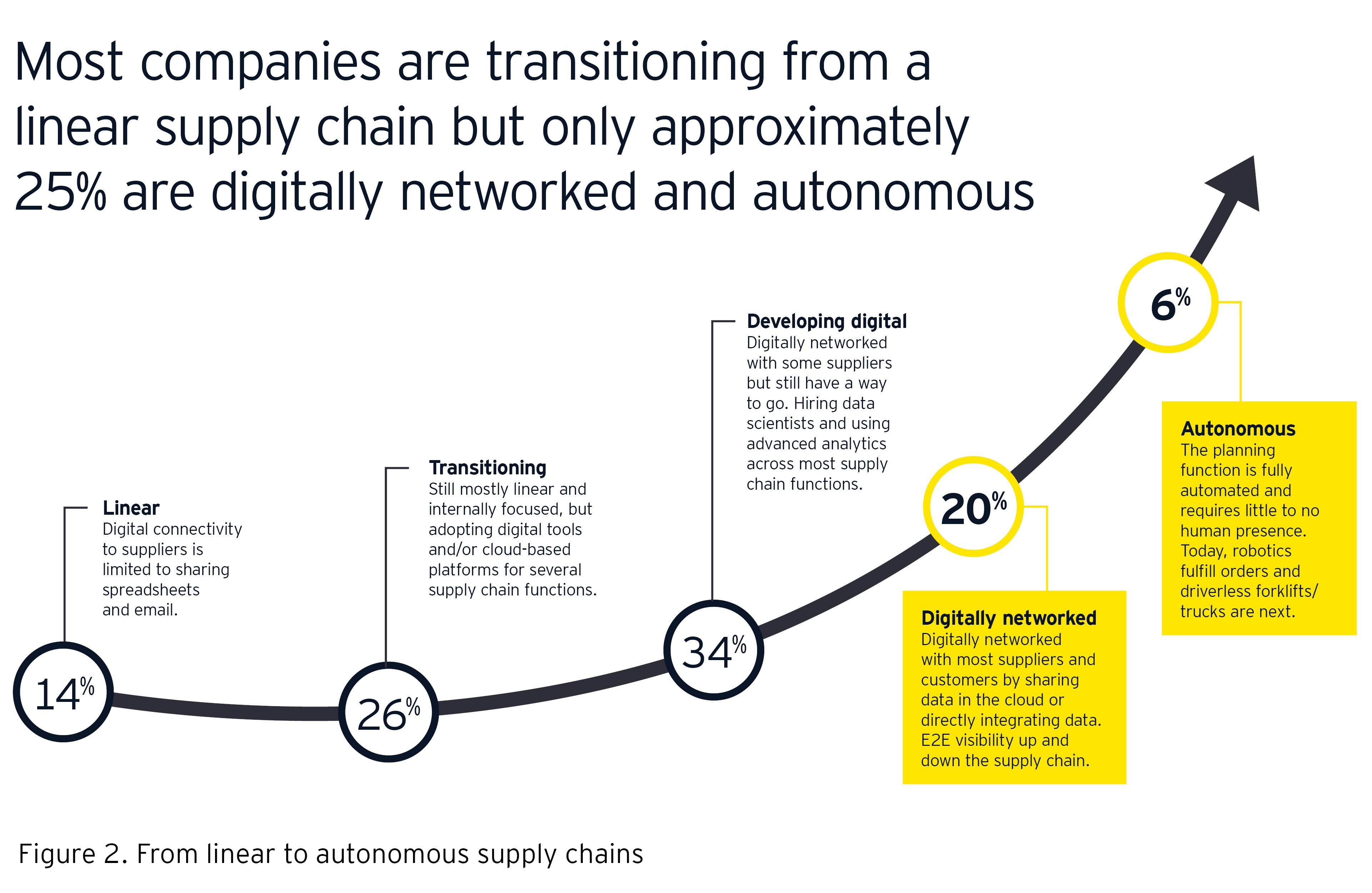

Supply chains are moving to becoming a networked ecosystem where all the data is in the cloud, and any event can be seen and acted on by everyone simultaneously.

The supply chain survey results also found that companies that are mostly autonomous are seeing significant gains in market share and customer satisfaction. 90% of respondents with a mostly autonomous supply chain say market share increased "somewhat/significantly" in the past year vs. only 7% with a linear supply chain. And nearly all mostly autonomous supply chains reported customer satisfaction somewhat/significantly increasing vs. 8% with a linear supply chain (figure 3).

3. Supply chain investment priorities

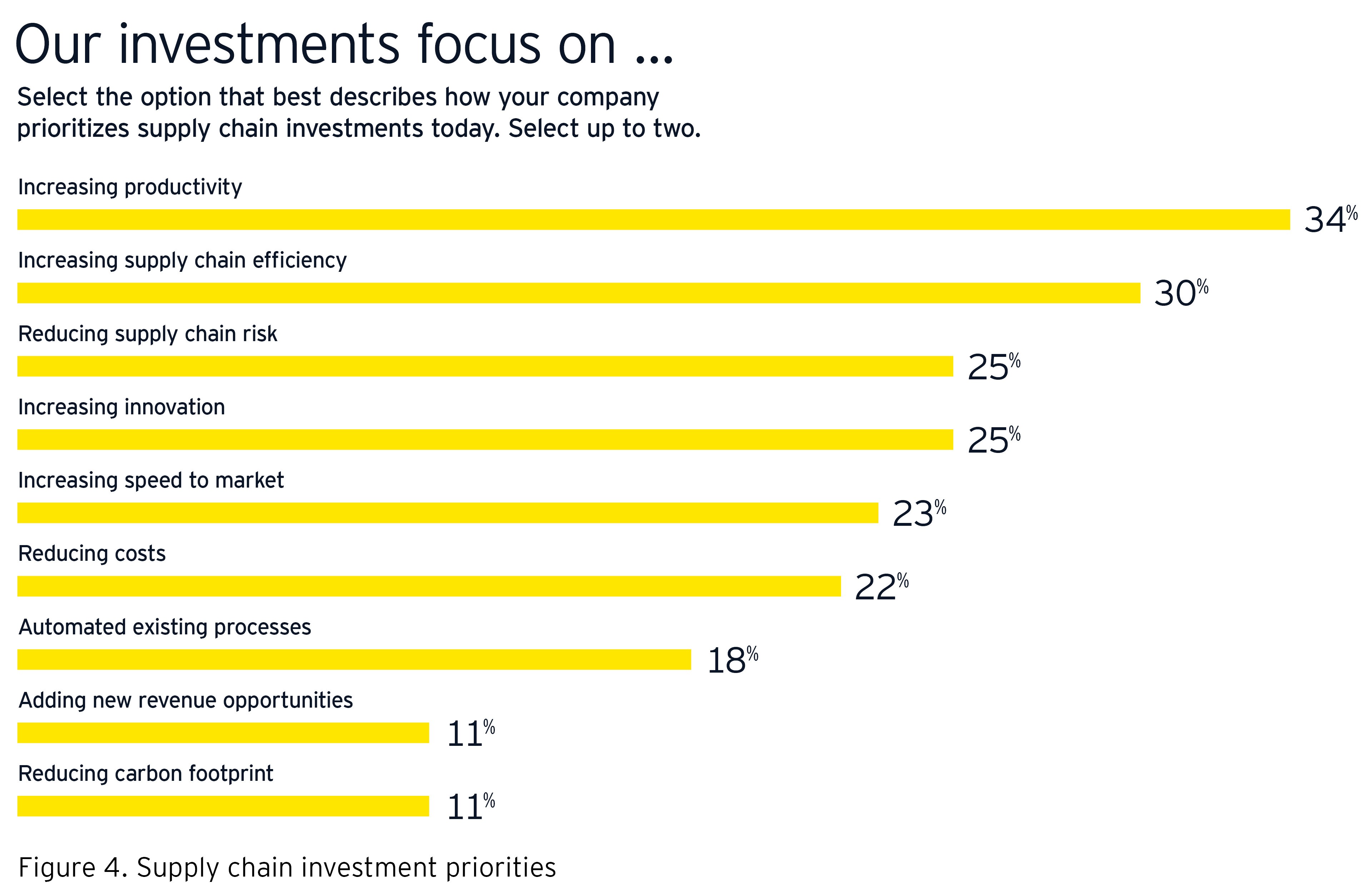

According to the survey results, investment priorities for supply chain executives are more focused on things that advance productivity, increase efficiency and mitigate risk (figure 4). This isn't surprising as firms want to get their foundation in place before digitally connecting with suppliers and customers.

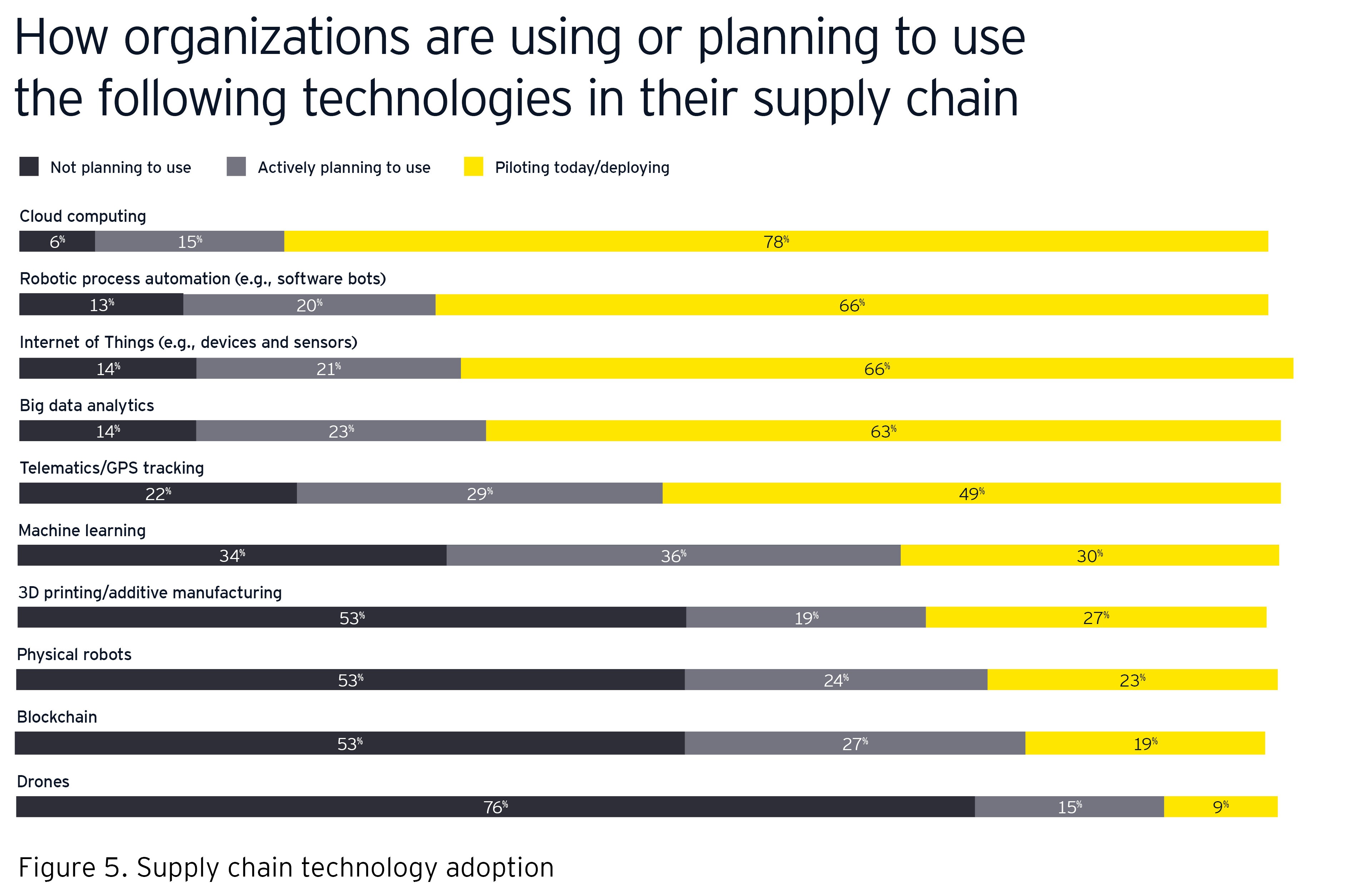

In terms of technology adoption, cloud, RPA, IoT, big data analytics and mobile/tablets were the top technologies selected by respondents to enable better collaboration, faster analysis and quicker reaction times to real-time events (figure 5). A key theme from the panelists was that companies should pilot emerging technologies with scale in mind — not as an afterthought. The research also showed that enterprises are experimenting with 3D printing, blockchain and physical robots.

Panelist Matthew Burton, EY Global Supply Chain and Operations Solution Leader, noted that while supply chains are viewed by many as a cost center, forward-looking executives see their supply chain as a way to effectively compete in the marketplace. He said, "Companies are using supply chain not just as a cost device but to actually fuel growth."

When the audience was polled about what best describes how your company prioritizes supply chain investments, 25% indicated increasing supply chain efficiency, and a close second (24%) was reducing supply chain costs.

4. Overcoming the talent shortage

It is no secret that people are the backbone of any successful operation, and as an industry transforms, so too must the talent that drives it. Supply chain leaders need to drive the vision and rethink ways of working to attract and retain the right talent. Every industry we surveyed agreed that their supply chain leadership embraces innovation. However, it's difficult to embrace innovation when your organization is constantly on the hunt for skilled employees.

The workforce must transform as the supply chain reinvents. This includes retraining, recruiting and retention of talented employees to prevent knowledge loss. Our survey also noticed a growing contingent workforce where 44% of companies are using more contingent workers than three years ago. This could indicate a talent shortage where enterprises are having to contract out with retired, but still very experienced employees, or go to staffing agencies for help in filling supply chain roles.

Survey respondents indicated that recruitment for the digital supply chain isn't easy, noting that lack of skilled employees is the No. 2 obstacle for a successful supply chain. It was noted that linear supply chains struggle the most with recruitment.

We need to market supply chain in a different way. It is now enabled by technology, leverages predictive analytics, and allows you to utilize all the bells and whistles.

When the audience was polled about which supply chain roles are the most difficult to fill, 30% indicated planning as No. 1, and 21% stated logistics and fulfillment as No. 2.

5. When to expect fully autonomous supply chains

The supply chain of the future has already arrived for some of our respondents. A small amount (6%) of enterprises either have planning functions automated with RPA and machine learning, and/or are now using robots to fulfill orders. For these companies, driverless trucks and forklifts are next. The reality and expectation is not if companies will have autonomous supply chains, but when. When asked about timing, more than 50% of supply chain SVP/EVPs said they expect mostly autonomous supply chains by 2025. These results were mostly fueled by automotive, industrial products, retailers and consumer products firms.

Sustainability is also top of mind for respondents. When asked about their supply chain priorities for the next three years, survey respondents cited sustainability as the No. 2 priority. Once a PR talking point, executives now realize that sustainability makes good business sense, in addition to being good for the environment. With improved means to gather data through IoT, and analyze data across the supply chain, it is now possible to quantify the financial benefits of sustainability.

When discussing the relevance of sustainability on supply chain, Glenn Steinberg said, "Sustainability is not a marketing ploy, it is not a corporate social responsibility kind of thing — it is a requirement." To which Regenia Sanders added, "Young people want to work for a company they believe in and want those companies to be corporate responsible citizens in terms of environmental impact and carbon footprint. Those things are critically important when younger professionals are choosing which company they want to work for."

As digital rolls forward and technology disrupts markets, change becomes the true constant. Now is the time for leadership to embrace change as an opportunity and a catalyst for future growth. This is the age of transformation, and supply chains are no exception. Company and supply chain leaders should consider these five topics as they grapple with what an autonomous future involves.

Summary

We highlight recent insights from a survey of 500 senior-level executives into what creates a successful supply chain. We discuss issues such as technology adoption, investment prioritization, supply chain maturity, leadership practices and sustainability.