Demand-driven planning and forecasting (DDPF) is a method that monitors and interprets demand in real time, actively shapes it and finds the best response.

Companies using DDPF are able to detect market changes five times faster and respond three times quicker than those employing traditional forecasting methods.(3) Sixty-one percent of best-in-class CP and retail companies cite demand forecasting as a game-changing capability, while 85% believe this capability is growing in importance.(4)

How can DDPF help your company?

Businesses using DDPF become much more closely linked to the market and pull driven. They can position inventory correctly, react swiftly to real consumption levels and underpin the success of their strategy by improving the accuracy of near-term forecasts. DDPF also enhances companies’ ability to shape demand.

From a marketing perspective, they can better compare the return on investment of different proposed activities because they can segregate baseline demand from the way demand behaves during promotions and events. They also have a much clearer picture of which outcomes are due to different facets of a promotion (10% off or 20% off; front aisle or center store; TV advertising or social media campaign) and which are due to extraneous factors (rival offers; weather conditions).

DDPF is forecasting on steroids. Instead of using one source of data — past shipments — you use nine or ten.

From a supply perspective, DDPF means that when companies have too many products they can proactively push the market to reduce stock, and when they have too few they can remove promotions to avoid creating false expectations and disappointing customers.

Warehouse management systems can predict what orders customers or consumers may be about to place out of particular distribution centers. Proactive picking can be employed to bring the inventory that is more likely to be required to the front of the distribution center ahead of time, which can save up to two days in responding to orders.

Key benefits of DDPF include:

- Decreased inventory costs as demand is forecasted more accurately

- Better customer service as stock is available when needed

- Improved supplier relationships due to smoother demand pattern

- Increased forecast accuracy with an integrated perspective

- Closer alignment with strategy

- Decreased operational costs as the need for firefighting is reduced

- Reduction in stock, obsolescence, write-offs and lost sales

- Improved on-shelf availability

Instead of having lots of different plans for the year ahead, all proposed activity is put into one overarching system. This is immensely valuable in making strategic decisions such as when and how to launch new products.

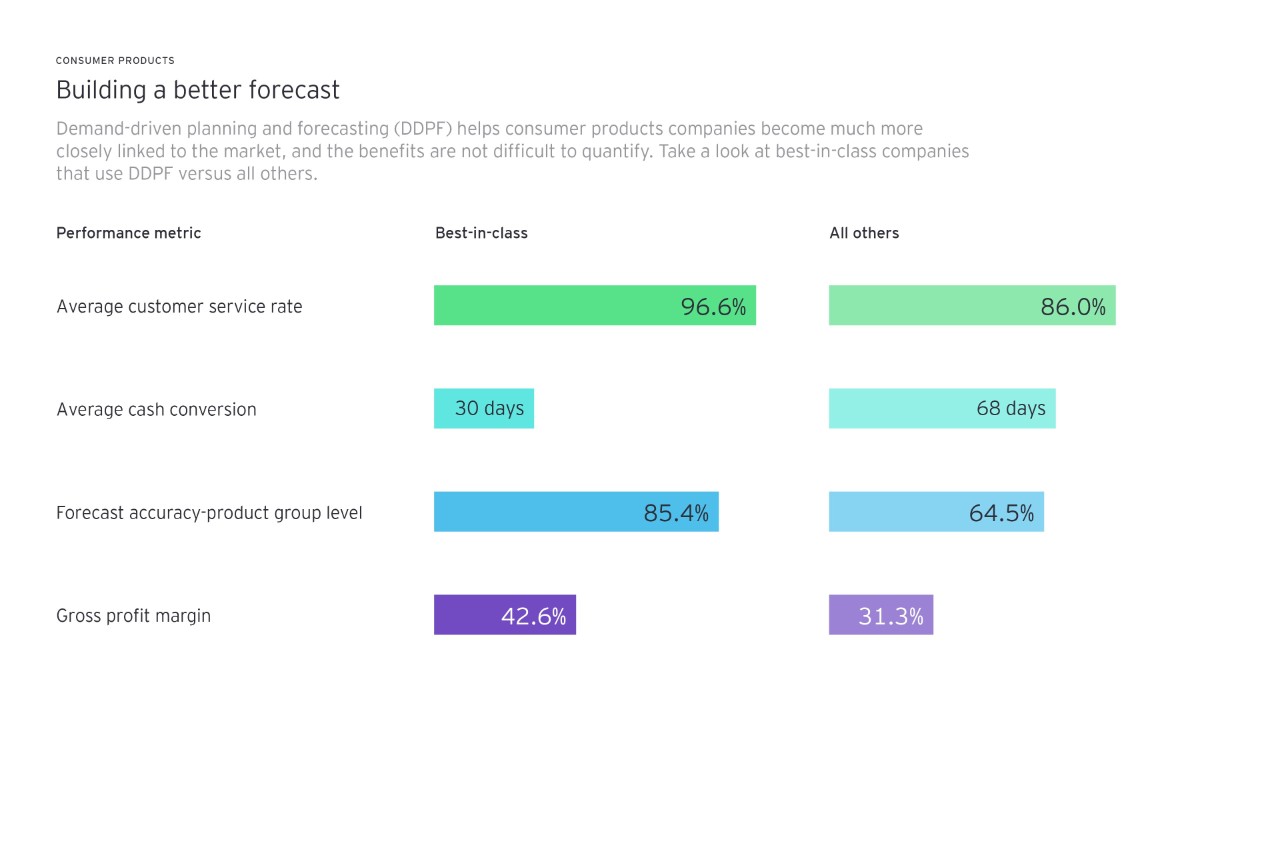

Comparison of best-in-class CP companies using DDPF and all others

Why aren’t more companies doing this?

Businesses using DDPF are still few and far between. Just 20% of CP companies are confident that they can rapidly align supply chain activity with changes in demand.(5) And only 10% say they are able to sense and shape demand.(6)

Why is this? A few reasons include:

- Lack of awareness of the value of the data they have

- Difficulty analyzing and using the vast mass of data being collected and stored

- Inability to combine internal and external data — compounded by the use of different and often incompatible IT systems

- Failure to understand bias — whether the company consistently over- or under-predicts demand levels

Companies using DDPF

5xSense market changes five times faster

Companies using DDPF

3xAlign their value networks three times quicker to changes in demand

How does DDPF work?

Rather than relying on historical sales as the primary data source, DDPF collects many different types of data including:

- Point-of-sale data

- Deliveries requested by retailers

- Stock situations at individual warehouses

- Trends on social media about particular products or brands

- Event-based data such as promotions, merchandising or weather conditions

Demand analytics monitor incoming signals for any kind of deviation from what is expected, interpret what that deviation means, and then develop an appropriate response. Techniques such as pattern recognition and machine learning enable the system to identify patterns and correlations: demand spikes or dips that happen every Monday, or in the last week of each month, for example.

When you have a more trusted demand signal you can properly segment and synchronize the supply chain, reduce manual work and manage the flow of goods and services in much more precise ways.

Much of the data can be gathered and input into the system by robots, while processing it is fast and affordable, thanks to technological advances. Sales, marketing, trade marketing, supply chain and finance teams gain the ability to collaborate rather than working in silos — sharing the same data and working to one single “point of truth.”

Promotional and marketing plans, customer plans and demand plans can be handled in one seamless process, with advanced predictive analytics mapping the likely results. Figures are also integrated and aligned across the strategic, business and financial plans, at varying levels of detail. All parts of the business and the whole network of partners including suppliers and customers have more trust in the process.

Game-changer

61%of best-in-class CP organizations cite demand forecasting as a game-changing capability

High demand

85%of CP companies believe demand forecasting is growing in importance

As more and more wearable devices and smart appliances come on line, companies will be able to see real consumption patterns in people’s homes and lives, and use this information to make DDPF even more sensitive.

How to move to DDPF

While cutting-edge technology and advanced analytics are vital, they are only enablers: a company also needs to have the right people, processes and mind-set in place to reap the full benefits of DDPF. In particular, it must invest in a data repository or data lake that is able to report complex data in a user-friendly way, and provide training and support for all those involved in the demand planning and forecasting process.

Seven steps to DDPF:

- Embed ownership of DDPF into the sales and marketing functions, driven by IT

- Develop consumer-driven plans by integrating sell-out and sell-in data

- Increase collaboration between sales, marketing, operations, finance and IT by introducing a common database

- Develop deep, strategic relationships with customers to support joint business planning

- Implement a unique set of event-based data, covering areas such as promotions, price changes, weather forecasts and competitor activity

- Introduce product, demand and customer segmentation to allow aggregate and SKU planning

- Create a center of excellence for demand analytics, employing the latest technologies, and appointing an internal demand management champion

Summary

By using demand-driven planning and forecasting (DDPF), companies are able to achieve collaborative, consumer-driven methods that enable them to better predict and control the outcomes of their supply chain.