COP26 has recently ended with an agreement that keeps the 1.5C goal alive. Even though the opinions about the results are divided, one thing is certain - the world is changing and the focus on sustainability is only increasing, with more and more politicians and business leaders implementing initiatives and regulations to support the transition to a decarbonized world economy.

With Gen Z increasingly using their climate-focused buying power, building on top of the climate pathway already laid by Gen Y, we see consumer trends shifting towards a demand for greater transparency. Consumers no longer want to just see a label or sticker on a product that describes whether or not that product is environmentally-friendly, sustainable, or produced in a socially responsible way - they want full transparency regarding sustainable sourcing, the origin of recycled raw materials, and a full life-cycle footprint of the product. Increasingly, this new generation of consumers wants to know what impact their buying decisions are making on the world.

This changing buying behavior is a major opportunity for sustainable and transparent businesses. These businesses can take market share or increase their revenue by charging a premium for their products, especially with younger consumers. EY’s Future Consumer Index shows that 43% of global consumers want to buy more from companies that make a positive difference to society, even if these products or services cost more. At the same time, 61% of consumers want more information on the product they purchase, to make more sustainable choices. Crucially, consumers are willing to pay more for products and services that offer such information.

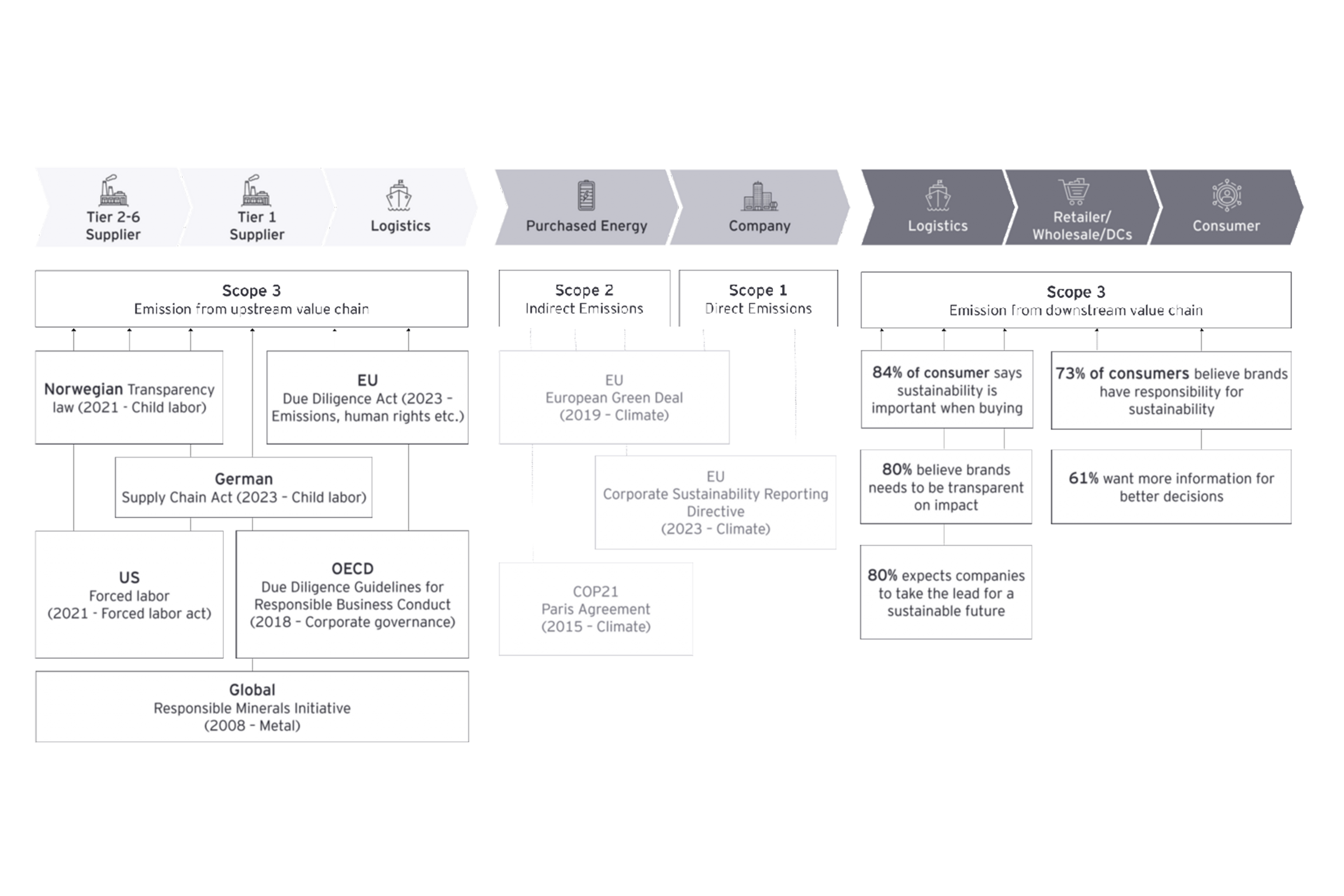

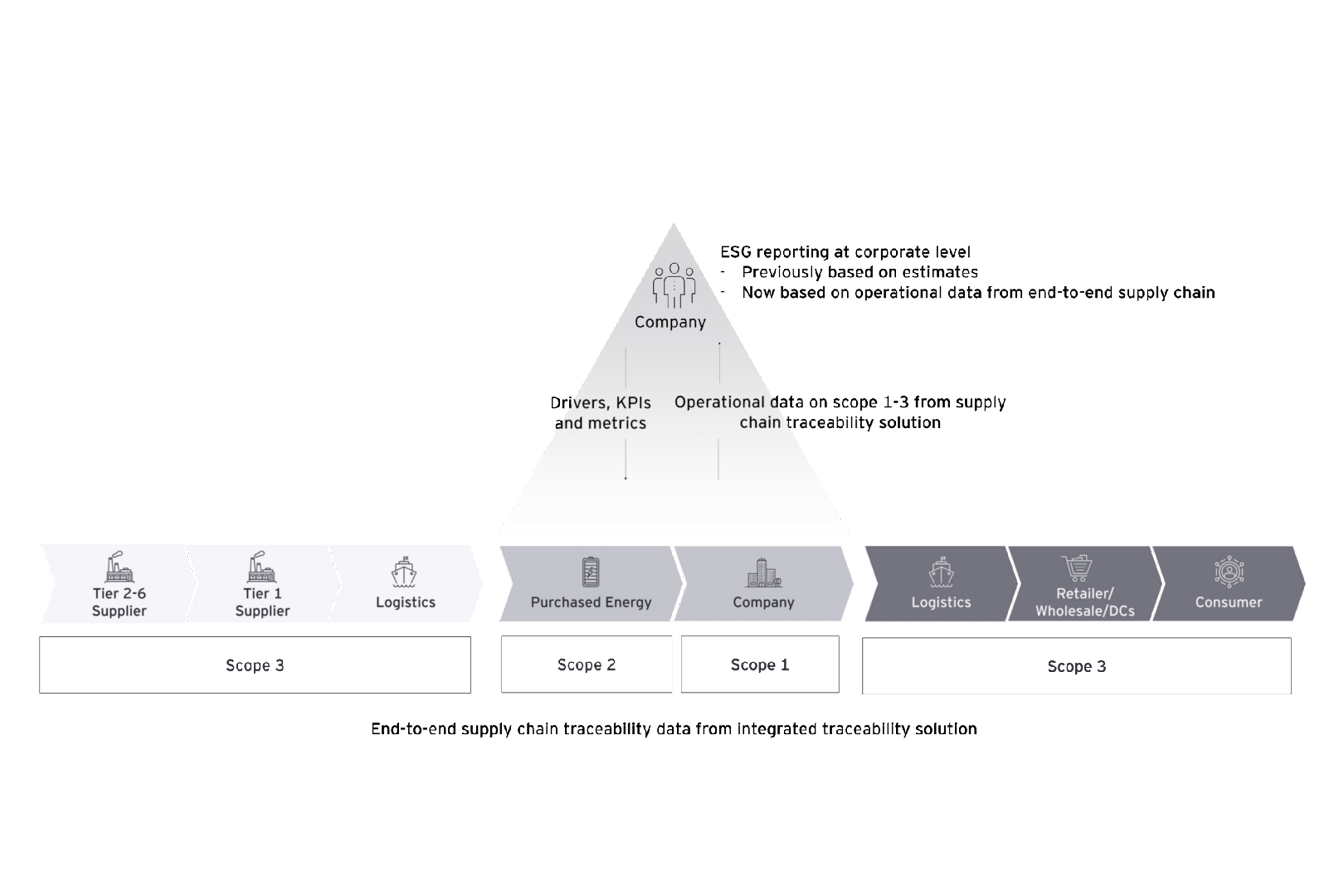

As a further driver of supply chain traceability, increasing global environmental and supply chain regulation may also increase costs and disrupt supply chains. To better understand where new and emerging regulations will impact companies across their supply chains, we need to understand the three scopes of the international Greenhouse Gas (GHG) Protocol. Under the GHG Protocol, GHG emissions are divided into Scope 1, 2, and 3, with each scope representing a unique part of a company’s supply chain

Scope 1: Direct emissions from company-owned and controlled resources. A company’s direct GHG impact on the wider supply chain, and its direct GHG emissions.

Scope 2: Indirect emissions, e.g. from buying electricity from a utility provider to use in a company’s office or factory.

Scope 3: Emissions that occur across the value chain of the specific company in question. This includes both upstream and downstream activities.

Seen through the supply chain lens, we could simplify Scope 1 and 2 emissions as relating directly to the company itself, with Scope 3 emissions relating to the end-to-end supply chain. For example, almost 99% of Apple’s carbon footprint relates to its Scope 3 emissions, with more than 80% of these emissions coming from Apple’s direct supply chain.