In response, manufacturers are prioritizing digital transformation and innovation-related investments. According to the EY January 2023 CEO Outlook Pulse survey, virtually all (97%) of industrial manufacturing CEOs indicate that continuing digital and technology transformation to deliver growth and operational advantages is either a very or fairly important near-term priority, despite near-term economic uncertainty.

Through these investments, manufacturers seek to revolutionize processes by implementing innovations such as digital twins, artificial intelligence and machine learning. At the same time, they are advancing product and service offerings across the value chain that are smart and connected.

However, to fully realize the significant opportunities arising from disruption and the value of these investments, manufacturers must tie them to a unifying vision of where their markets are headed.

A different, innovation-focused approach to manufacturing transformation

Forging a new path to the future will require manufacturers to put their growth agenda at the center of transformation. This plan needs to be backed by a detailed strategic roadmap that accounts for both the innovations needed to succeed, as well as the transformation required to launch and scale these breakthroughs in the market. It must also be developed with an enterprise-wide outcome in mind, breaking down functional and geographic silos.

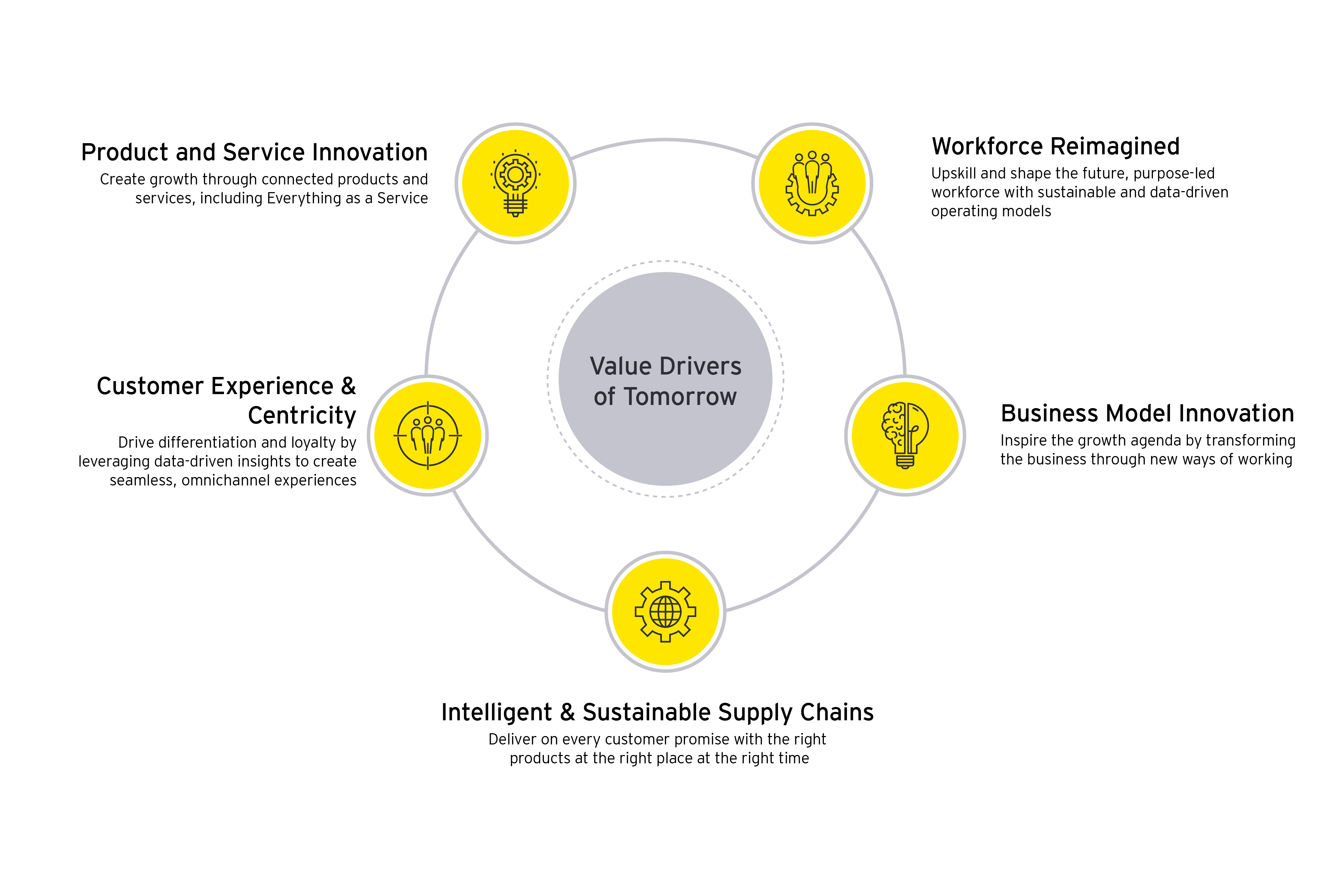

While not every initiative needs extensive cross-organizational coordination and buy-in, many of the most prominent areas for manufacturers’ business reinvention are inherently interdisciplinary. Effective transformations demand engagement with a range of intersecting value drivers, including product and service innovation; customer experience; intelligent and sustainable supply chains; workforce and talent; and business model innovation.

(Learn more with Advanced Manufacturing Realized — via EY.com US)

The value drivers of tomorrow

Once a decision is made to pursue small- or large-scale reinvention, manufacturers can maximize the speed, agility and long-term value generation by adopting the following best practices.

Chapter 1

Start with the end in mind, but also know where to begin

Use a future-back approach to explore potential opportunities.

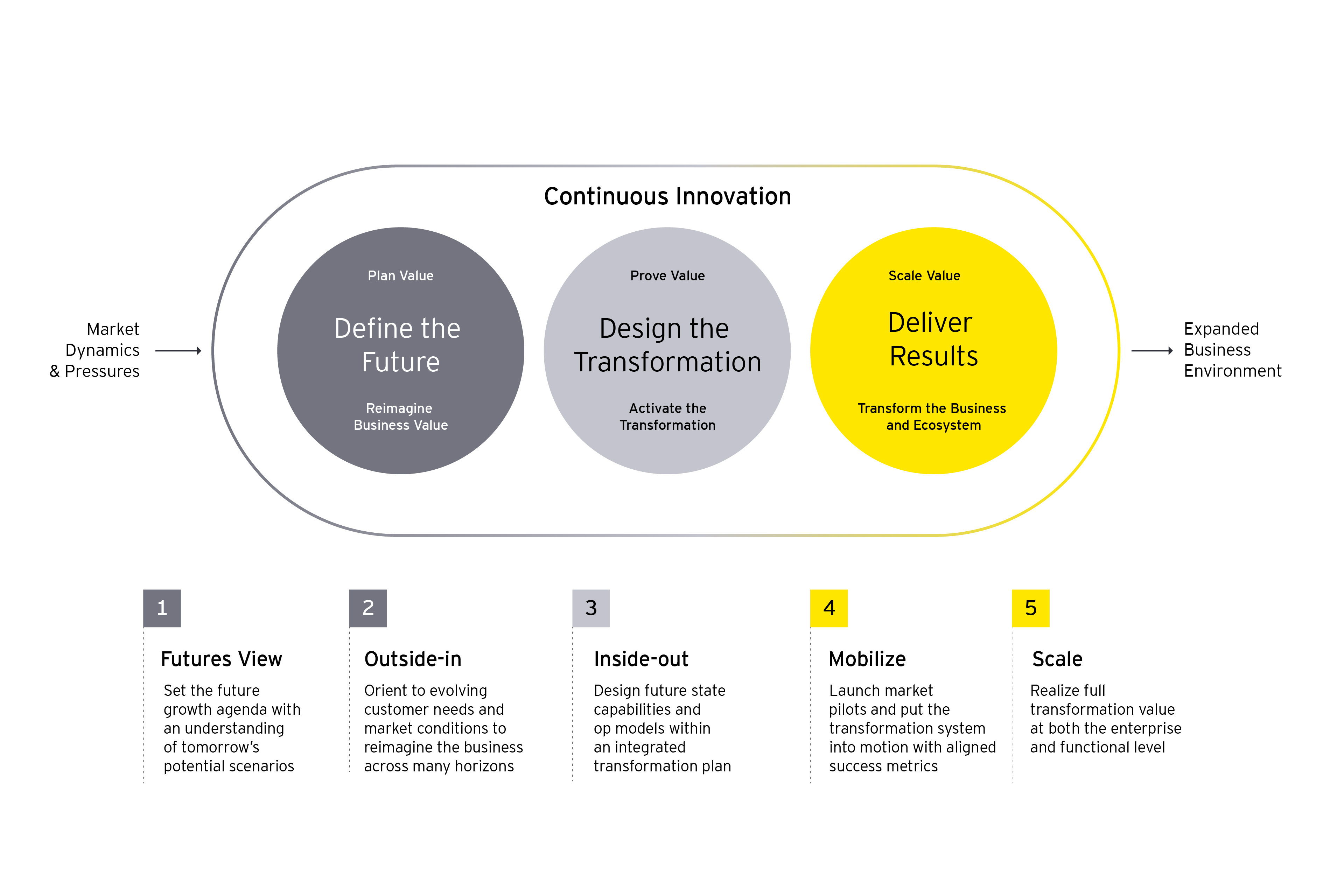

With business challenges clearly defined, manufacturers should explore solutions using a future-back approach that starts with the end in mind. The critical first step involves rapidly defining and assessing tomorrow’s potential futures from the outside-in, and predicting how these future scenarios may shape customer needs, market conditions and value pools across time horizons. In parallel, organizations must also perform a thorough review of their current capabilities, particularly those that may play an increasingly important role in future competitiveness.

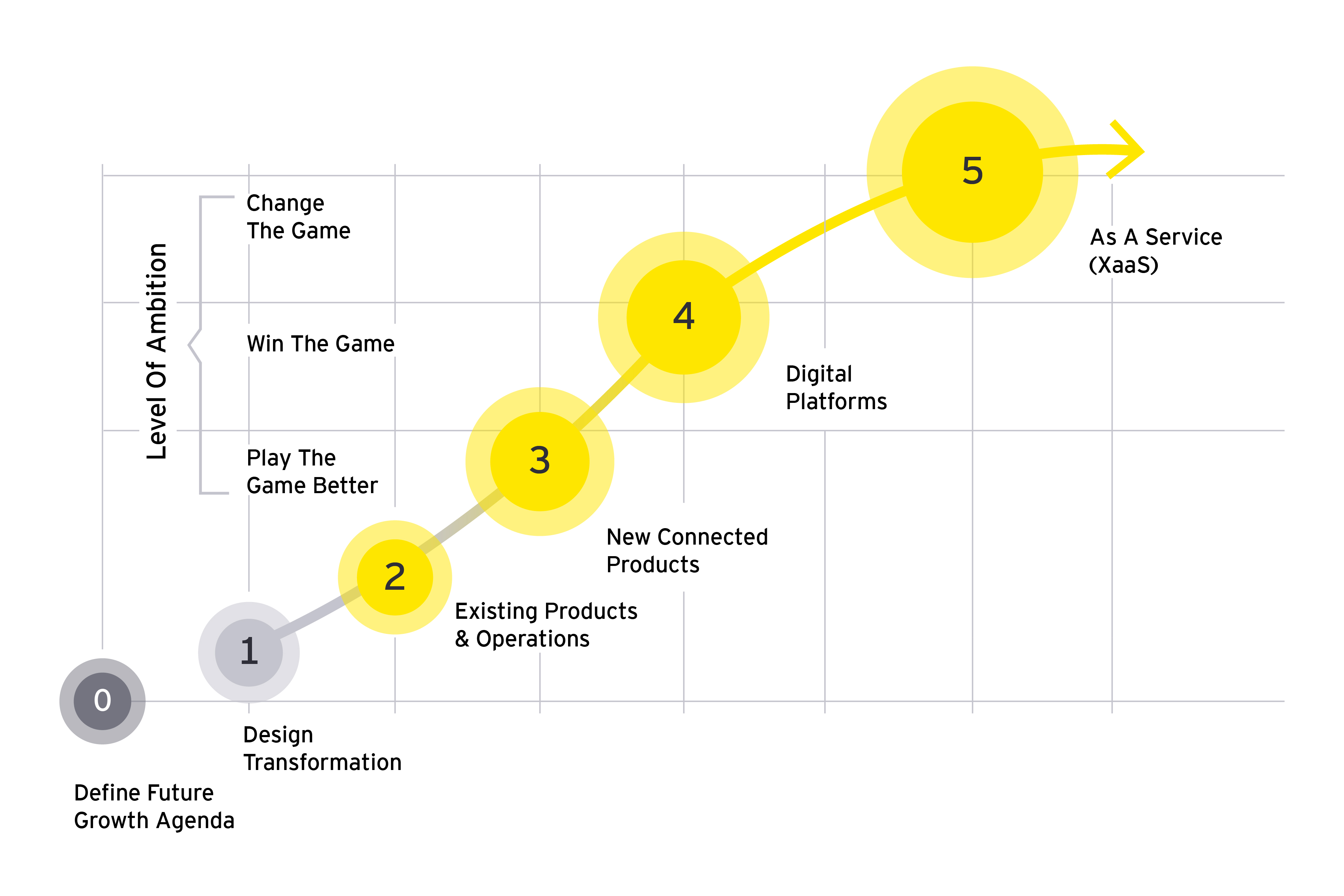

Taken together, assessments of a company’s current state and potential futures serve as the foundation of a new strategy that will act as the transformation’s “north star” – guiding it relative to the level of ambition, while optimizing development speed and investment spending. This strategy should also provide a framework for cross-enterprise transparency and engagement.

Our approach to transformation

Chapter 2

Design the transformation with a hands-on approach to innovation

Conduct rapid prototyping to substantiate future views and refine perspectives on must-have innovations.

Rapid prototyping is an essential step for manufacturers to substantiate their future views and refine perspectives on must-have innovations. Multiple, accelerated iterations of both physical products and digital offerings are important for assessing features and costs in the context of various customer expectations, demand levels and competition scenarios.

Making the future tangible will pay dividends in the design phase of the transformation. Understanding necessary enterprise-wide adaptations – from specific technology or talent enhancements to new business models – will inform an achievable, cross-functional plan. The ability to “show your work” will also help build support across various internal constituencies as they are enlisted in the effort.

Start with the end in mind

Chapter 3

Accelerate results by incubating new business model concepts

Prioritize small-scale experimentation using a start-up style approach.

When future growth depends on technologies, customer expectations or new value pools that are not addressed by a manufacturer’s current core competencies, innovation at the business model level may be a solution. For example, what are the implications of collecting, analyzing and monetizing data from a new connected product? Successfully assessing and addressing these impacts could enable manufacturers to leapfrog the competition.

Given the enterprise-wide implications of such changes, legacy manufacturers should prioritize small-scale experimentation with a lean, internal start-up style approach. In conjunction with ongoing physical product innovation, manufacturers will want to invest in teams to explore the internal and external infrastructure and capabilities needed to support an operating model for an offering’s full lifecycle. This approach can be particularly beneficial for evaluating the technology infrastructure required for a potential new business model. By using focused, lean teams, manufacturers can leverage agile sprints to further define capabilities and architectural requirements as the transformation progresses.

Chapter 4

Identify ecosystem partners to address critical capability gaps

Structure a process to assess potential collaborators across a range of factors.

As manufacturers innovate, they will have to decide whether their long-term strategies are better served by seeking ecosystem partners versus internally developing or acquiring new capabilities. Assessing targeted value pools and key differentiators of success can help inform these decisions.

Manufacturers whose future offerings are likely to depend on the secure sharing and analysis of data at scale will want to consider partnering with technology providers as a more efficient path to market. However, the factors to consider when choosing a mission-critical partner can be extensive, particularly given the high cost of potential failure. Legacy manufacturers can benefit from a structured process to weigh the benefits of various collaborators.

Manufacturers exploring business model innovation may also find a need for ecosystem partners outside of the technology sector. For example, future mobility business models may involve close collaboration among vehicle OEMs, energy, infrastructure and insurance firms. When framing new relationships with potential commercial partners, manufacturing leaders should take an active role in defining their organization’s positioning and contributions so that the partnership’s value is distributed equitably.

Chapter 5

Key questions for manufacturers considering reinvention

Answers may help to address critical gaps.

The urgency around transformation has escalated as manufacturers grapple with multi-faceted disruptions. Reactive, short-term focused responses limit the vision for enterprise-wide transformation. When thinking about the right approach, manufacturers should consider the following questions:

1. Product and service innovation: How do we evolve our product portfolio to create dynamic products and services that address customer demands for smarter and more connected features, customization, and safety/security?

2. Customer experience: How does a shift from B2B to B2C or D2C impact how we operate today?

3. Operations:

a. How can we leverage emerging technologies to future-proof our supply chain?

b. How do we design our future manufacturing capabilities as a competitive differentiator?

4. Workforce and talent: How can we advance innovation as a core capability through hiring, developing, training, and incentivizing our employees?

5. Business model innovation: How do we innovate to drive the core business to peak profitability while simultaneously incubating new growth engines?

Answers to these questions may help leaders address strategic or operational gaps. With a clear vision of their organization’s future ambitions in mind, and a strong strategy for innovation-focused transformation, leaders can position their organizations to accelerate growth and leapfrog their competition.

Thank you to Shelby Koons, Business Consulting Manager, Ernst & Young LLP; Nikhil Jalgaonkar, Business Consulting Manager, Ernst & Young LLP; Johan Tioanda, Consulting Manager, Ernst & Young LLP; Jenna Lin, EY Consulting; Harsha Anand, Knowledge Manager, Ernst & Young LLP; and Mayukh Chaudhuri, Strategy & Transactions Manager, EY Global Delivery Services for contributing to this article.

Related articles

Summary

A range of disruptive forces have shifted operational priorities. Legacy manufacturers urgently need a better way forward. An innovation-led approach that incubates future opportunities while optimizing current products and operations can provide value-driven solutions for the short term and long term.