In the face of increasing supply, demand and financial volatility, optimizing cost performance is essential to support business objectives.

Companies are currently facing the following challenges:

Financial Uncertainty

Market volatility and disruptive events are leading to increasing prices of raw materials, goods, services and energy, which is affecting overall business performance and profitability. While cost cutting becomes a priority in supply chains, financial pressure and volatility keep on growing.

Supply Disruption

Upstream supplier constraints result in extended lead times or even complete supply interruption. This requires costly measures to maintain service levels towards customers (e.g. expedited freight, higher-cost alternatives, etc.). If supply disruptions are not appropriately handled, this will often lead to the loss of customers or partnerships.

Demand Volatility

Sudden unplanned changes in demand can disrupt your operations and increase both stock levels and overall cost to serve. This limited ability to respond causes increases in supply -, manufacturing - and logistics costs.

Manufacturing Flexibility

There is an ever-increasing need for production flexibility to quickly react to both internal and external events. Misalignments between the capacity of manufacturing plants and market demand can result in costly excess capacity or costly efforts to manage capacity constraints.

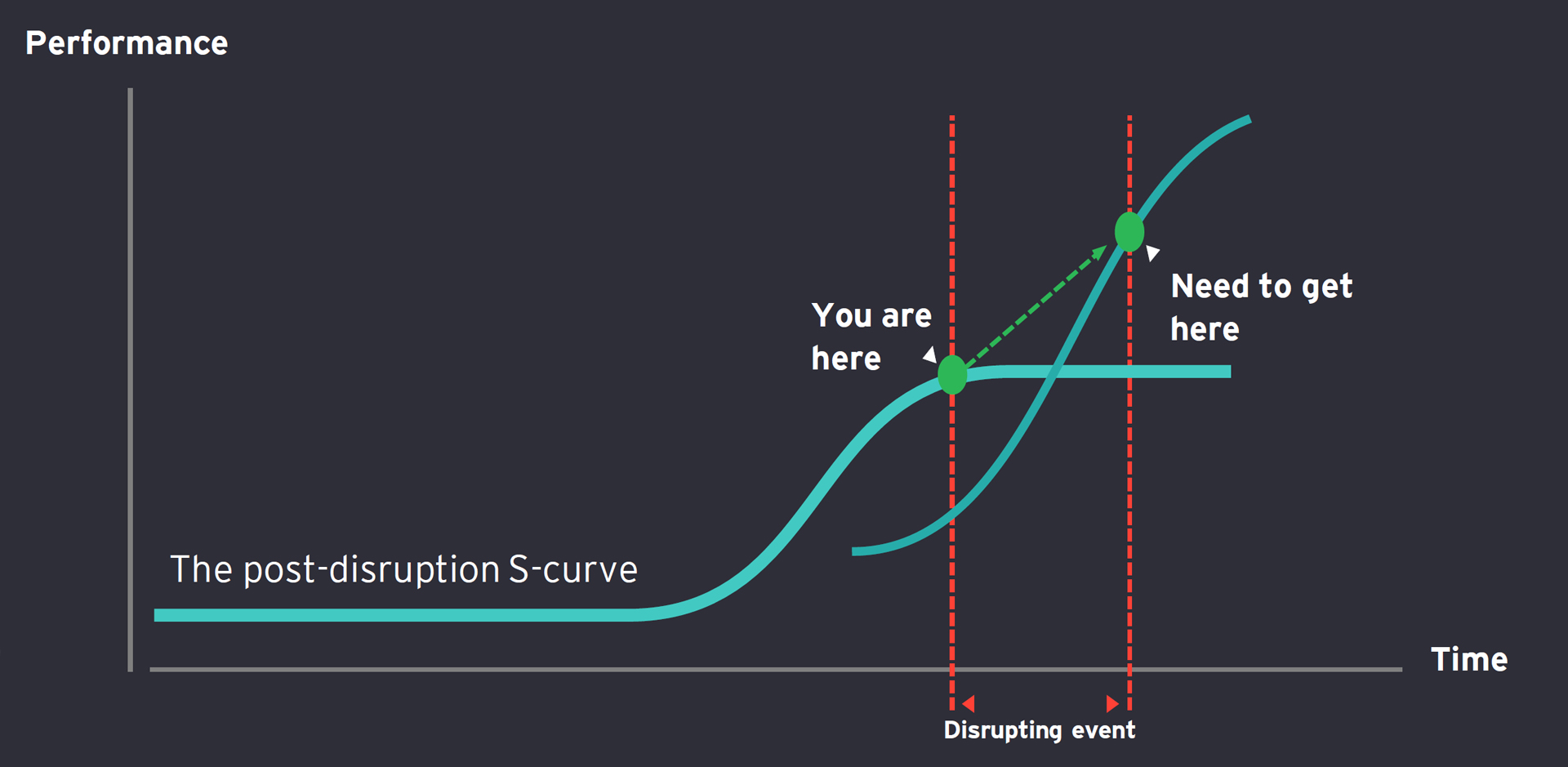

Companies that act proactively and streamline their supply chain can leap ahead of the competition.

Streamlining your supply chain offers benefits beyond improved financials

A methodical approach to cost optimization can fund your transformation journey and increase revenue. The overall objective is to reduce enterprise costs through supply chain cost levers to drastically improve margin in a sustainable manner. The levers will vary depending on the company’s business model but applying EY’s hypothesis-driven methodology provides a structured approach to rapid and sustainable cost reduction. This creates a new margin that:

- Increases shareholder value by directly improving the bottom line and increasing the return on investment.

- Empowers future investment in supply chain resilience and sustainability, leading to further business growth.

- Improves supply chain resilience by providing leaders the right level of transparency to truly understand the end-to-end cost of operations, allowing them to take appropriate measures to mitigate potential disruptive events.

- Optimizes and streamlines capex and working capital, refining the real estate footprint and guaranteeing the realization of tax efficiency.

A key success factor is moving from one-off cost reductions toward recurring, sustainable savings.

EY Supply Chain & Operations uses APQC OSM Benchmarking Data to benchmark your company's data against the industry's very best. This allows us to quickly identify optimization opportunities and develop sector insights for clients. The quantification of performance gaps against comparative groups supports EY SC&O’s methodical approach to cost optimization.

There are 6 core areas to drive sustainable supply chain cost reduction

Portfolio simplification

A smart rationalization of the product portfolio reduces complexity and cost across the end-to-end supply chain. This results in a streamlined and cost-efficient product portfolio that avoids erosion of the bottom line.

Procurement

An in-depth procurement spend analysis can bring about significant savings. Collaborative spend management optimizes value for money while delivering business goals.

Operations Network Footprint

Enables finding the right footprint to produce and deliver products to the customer, by leveraging economies of scale and reducing unneeded space, labor and routing to optimize cost while ensuring service level requirements.

Supply Planning

Stabilizes and optimizes the value chain across the end-to-end flow of the supply chain. Improves the working capital.

Manufacturing Optimization

A focus on improving asset utilization and throughput or reducing maintenance costs and downtime leads to an improved bottom line.

Supply Chain Target Operating Model

Defines the optimal organizational structure for every aspect of the supply chain.

Once identified, key levers can be split into NOW, NEXT and BEYOND. This enables the immediate benefits of quick wins while also setting the course for a cost reduction roadmap that will generate ongoing and lasting improvements.

The implementation of cost reduction strategies also reveals potential improvements in the company’s operating model. Supply chain leaders should opt for a more cross-functional approach, moving away from one-off cost reductions towards recurring savings.

Newsletters EY Belgium

Subscribe to one of our newsletters and stay up to date of our latest news, insights, events or more.

Summary

The growing complexity and strategic importance of supply chain, as well as the challenging economic environment in which companies operate, allow organizations to leap ahead of the curve by implementing integrated and sustainable cost transformation strategies.