Chapter 1

A fresh look at value proposition

Why companies need to rethink their business models and transition to a circular approach

Availability of resources is one of the most important factors for the long-term prosperity of companies. Growing global demand for raw materials is increasing scarcity and driving up prices and volatility. The resulting pressure on corporate supply chains can become an existential threat to companies. At the same time, today’s consumers are seeking a value proposition that goes beyond economic value to also include social or environmental benefits of a product or service.

Embracing green H2 – where it makes sense – is one way that organizations can reduce their greenhouse gas emissions, support long-term price stability and eliminate or minimize negative health impacts resulting from the pollution associated with fossil fuels.

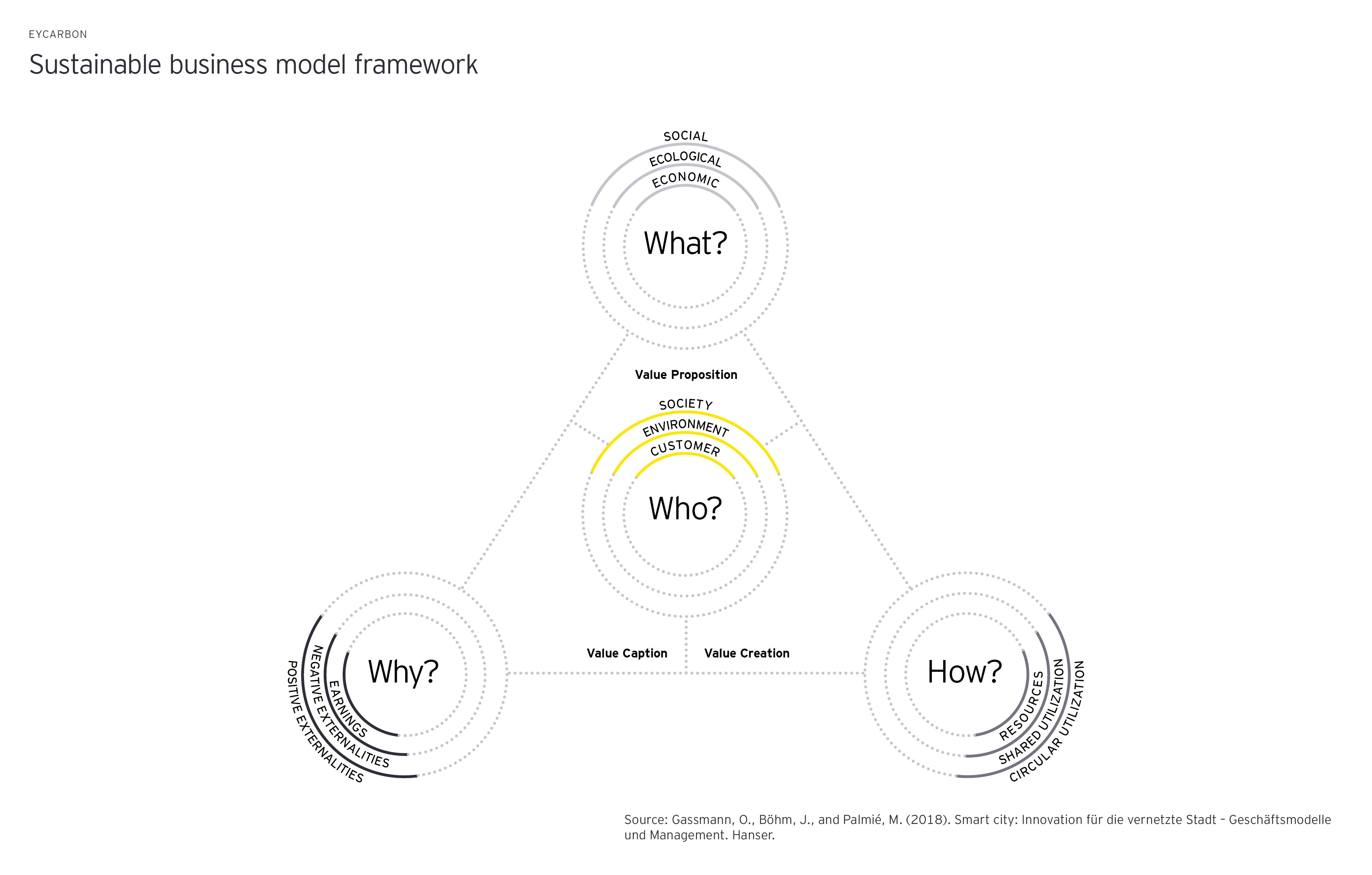

The smart city business model framework illustrates nicely how a value proposition can go beyond traditional views on economic worth. It identifies elements of business model and puts them in the context of sustainable innovation. To go from a traditional to a circular business model, firms do not need to change all four elements of their business model (what, how, why, who), just two. This approach naturally transforms the traditional linear business model, which neglects the potential to use by-products or exchange resources, into an ecosystem where cross-sectoral exchange is viewed as central to collaborative innovation and circular business models. When multiple businesses in an ecosystem apply circular business models, you get the beginnings of a circular economy (CE).

Chapter 2

Decoupling resources and impact

How hydrogen supports circular economy practices

The ultimate goal of a circular economy is to decouple economic growth from the degradation of natural capital. This means decoupling resources to reduce the utilization of finite resources on the one hand, and decoupling impact to reduce the generation of emissions, waste and other negative environmental impacts on the other.

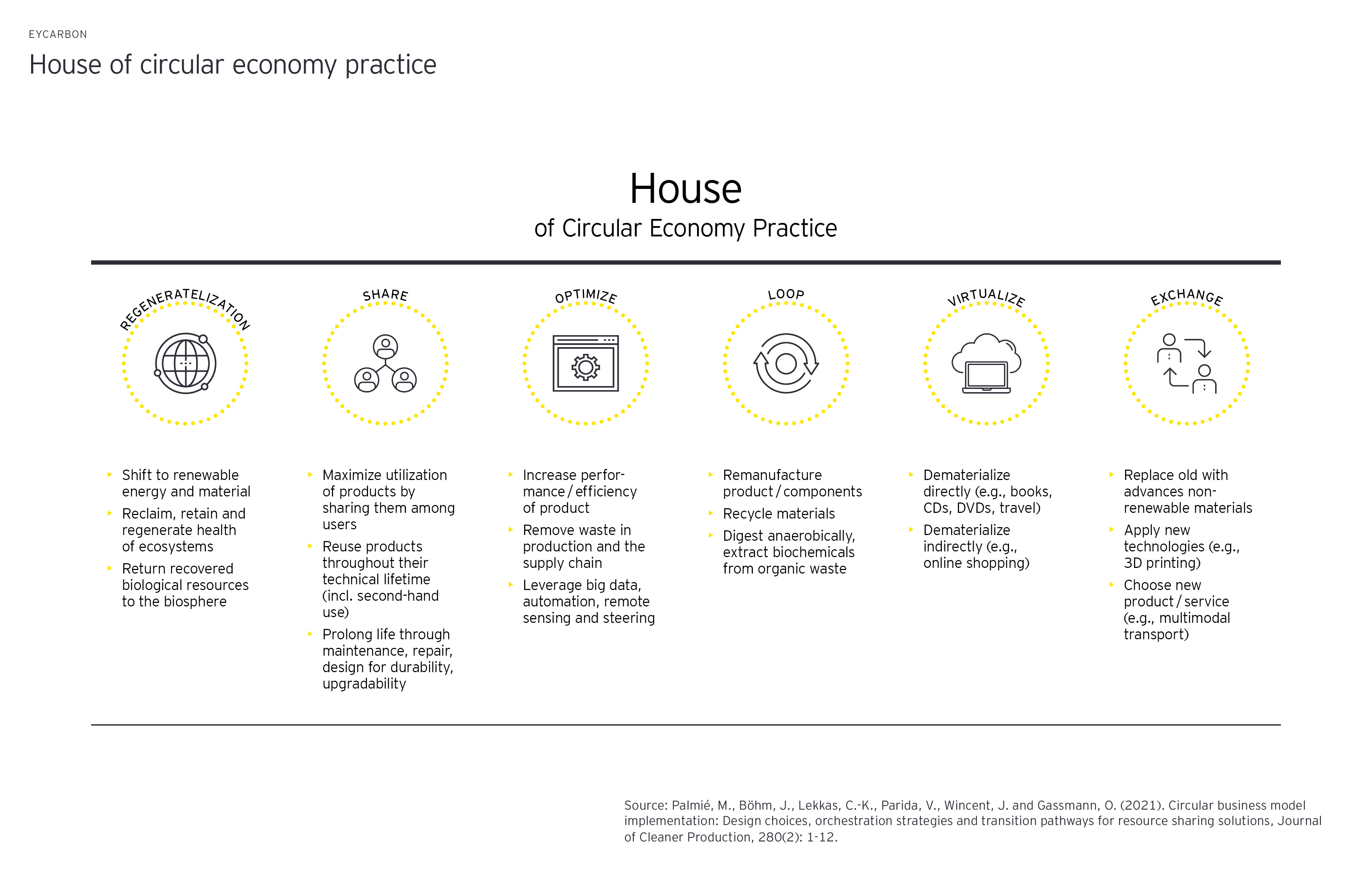

A circular economy reduces the material throughput of the economic system by not only closing but also reducing gaps. In the house of circular economy practice, hydrogen finds its place in particular under:

- Regenerate – use renewable power to produce hydrogen

- Optimize – continue to develop and refine hydrogen technology

- Loop – Recycle materials and use waste products

- Exchange – switch to green instead of blue or gray hydrogen

Given the complex nature, limited production capacity and enormous energy input needed to produce green H2, different hydrogen production streams from many different organizations may be needed. Certain practices can support the transition from a linear energy-and-material flow model to a circular business model. These practices would enable companies to reuse green hydrogen or restructure their material flow – if necessary, and where it makes sense –to obtain H2 as a byproduct, for example from chemical, wood or plastic waste.

Chapter 3

Getting the most from hydrogen’s potential

Three criteria reveal three priority application areas

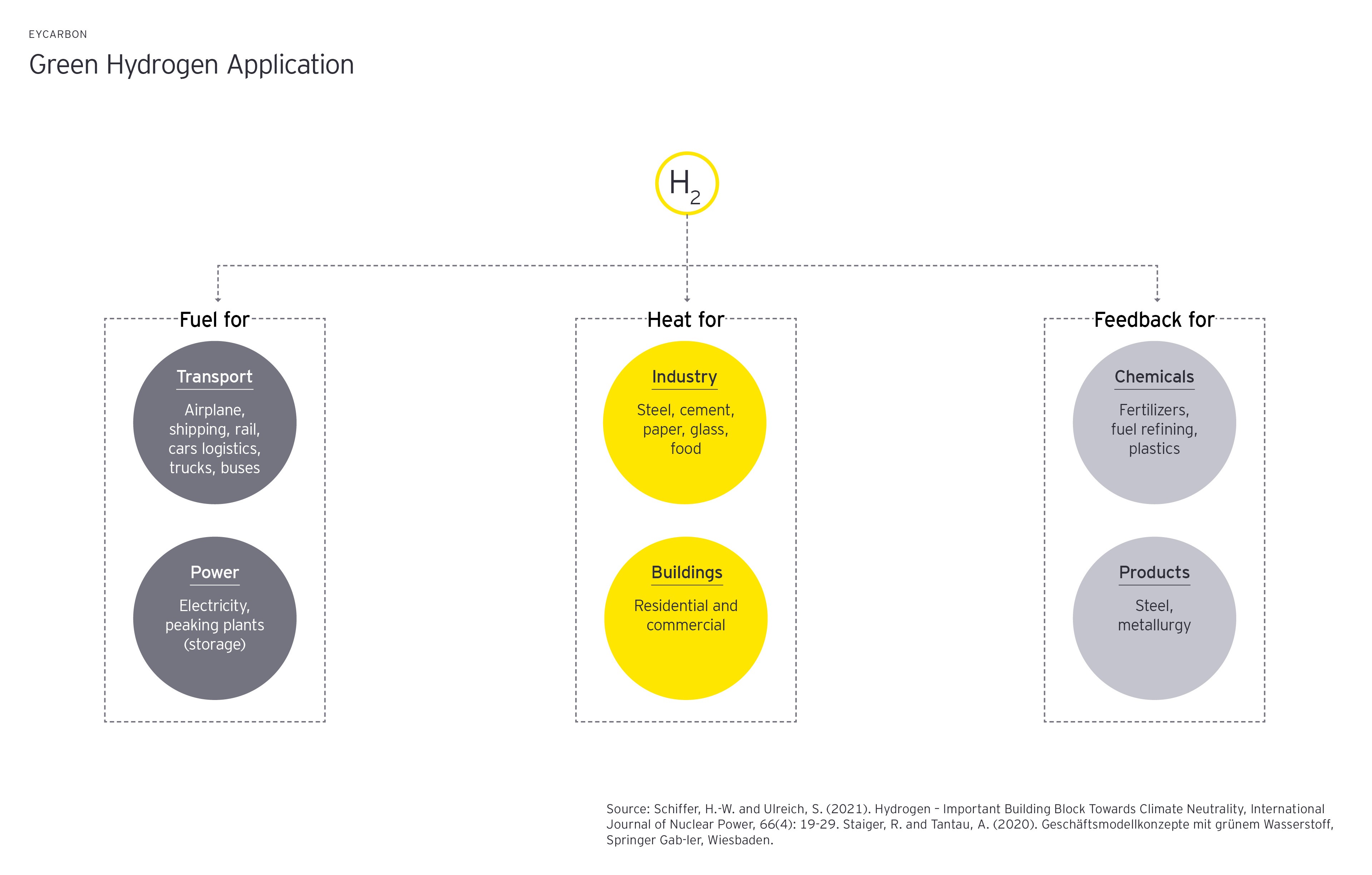

While the use of hydrogen is conceivable across sectors, application areas should be individually assessed to get the most efficient value from H2. Considerations shouldn’t simply be limited to technical feasibility, rather should focus on the contribution to long-term sustainability goals based on the following three criteria:

- Potential for decarbonization

- Potential and market readiness to include hydrogen

- Circular economy potential

Applying these, three priority areas emerge: fuel for transport and power, heat for industry and buildings, and feedstock for chemicals and products.

Now it's your turn!

To tackle climate change and meet carbon reduction targets, we need a shift in mindset toward a circular economy. For some, green hydrogen could feature as the missing piece in the decarbonization puzzle. Regardless of sector, though, business leaders can apply CE principles to transform their value proposition, create long-term value and make a sustainable impact.

Summary

Governments and corporates alike are considering how green hydrogen could super-charge decarbonization efforts. While H2 is unlikely to oust other green solutions like electrification, its use in various applications could close gaps and contribute to a truly circular economy.