Digital led supply chain transformation

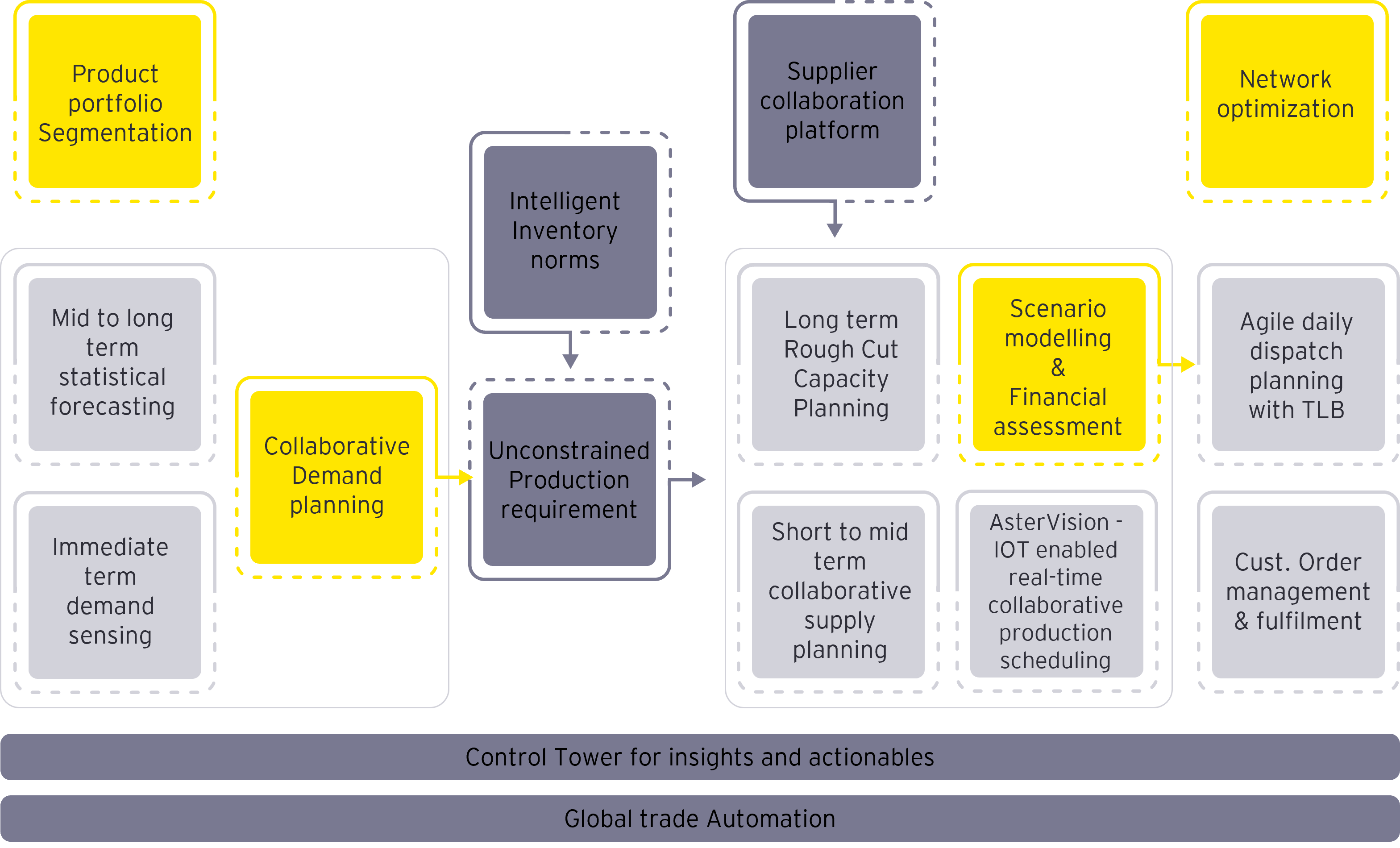

AI-enabled digital platform comprising 20+ modules each addressing client’s specific needs for digitizing and streamlining supply chain planning processes. The platform also offers sector specific customizations incorporating nuances peculiar to the respective industry.

EY Asterisk Supply chain platform

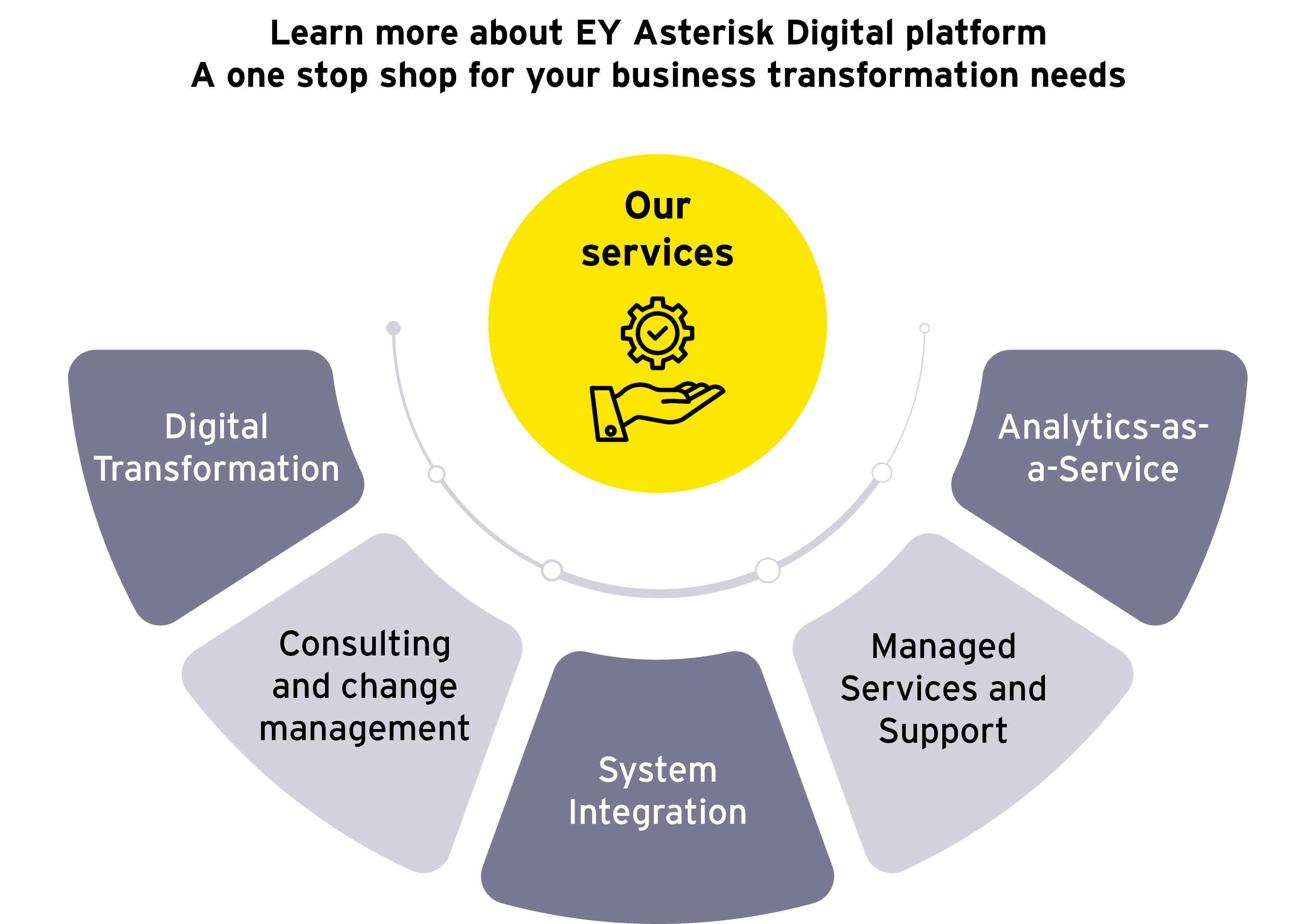

ASTERISK SC digital solutions comprises of integrated and AI - enabled end-to-end Supply Chain Planning modules

EY Asterisk Digital Platform

EY Asterisk’s AI enabled solutions with ground-breaking technology platform is successfully transforming businesses across industries and geographies.

Contact us

Interested in the changes we have made here,

contact us to find out more.